in:sure är en forsknings- och utbildningsmiljö vid Tekniska högskolan i Jönköping som utvecklar kunskap och förmågor relevanta för övergången till en helt integrerad produktframtagningsprocess som stödjer resiliens och hållbarhet i framtida produkter och produktionssystem.

Bridging Product Development and Production Using Production Requirements

Imagine, beginning a day without that first cup of coffee. Pressing a button on the coffee machine makes the process so much easier. Imagine, being on different corners of the world away from your loved ones, how products such as mobile phones or computers bring them nearer to you. You are a person who enjoys spending time with your family, imagine the products makes the day-to-day activities simpler, saves you time to provide more opportunities for safer and quality time with the family. Products, they make our lives simpler, but product development is a complex process.

Product development is a key activity of any economy where value creation is based on the needs of the customers. It is also an activity that is influenced heavily by changing customer behaviour, consumption trends, regulations, and geopolitical issues. Focus on sustainability and circularity creates a mix of new and legacy products, creating huge variations in customer requirements and product portfolios. Manufacturing companies are continuously working with improving their efficiencies which is good for both the customer and the society as it lowers the cost and the use of material and energy. The efficiency of product development is influenced by the amount of knowledge that is available to product developers to make accurate decisions during the fuzzy front-end where design flexibility is high, cost of change is low but at the same time product knowledge is also low. Knowledge about the production capabilities can support decision-making by design engineers during early product development phases and help manage uncertainties to an extent.

How to support design engineers with the right production knowledge at the right time?

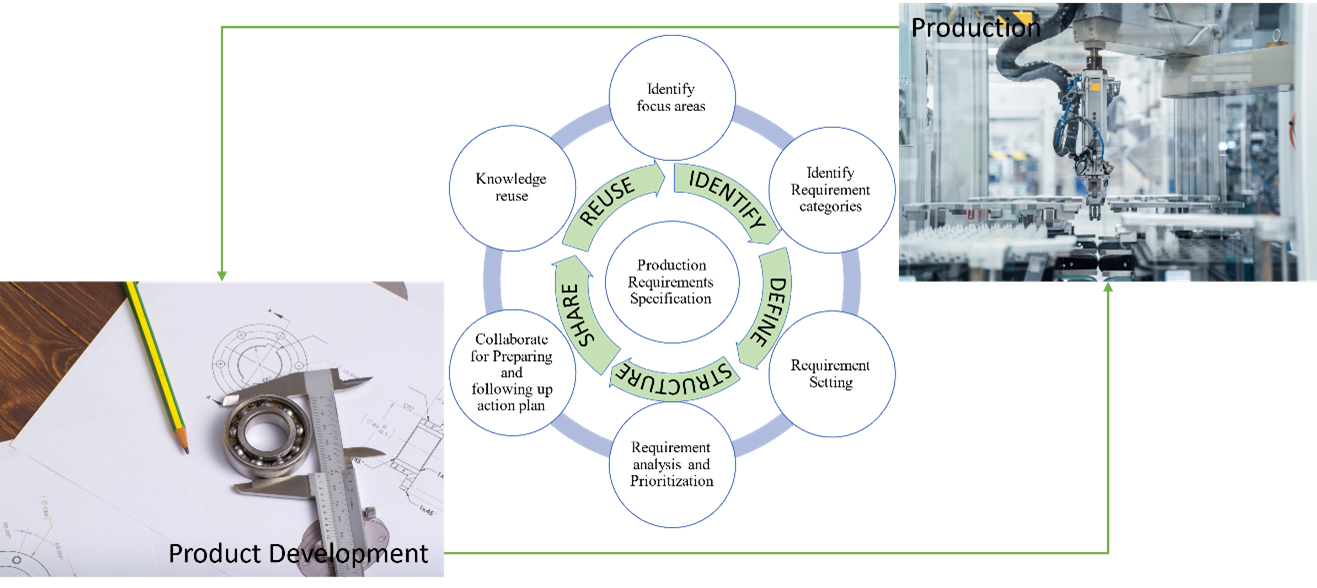

Requirements are the drivers of product development. Often, the term requirements pull attention towards the external customers, the end users. But what about the internal customers and stakeholders? What about the requirements from manufacturing that play a crucial role in the success and timely introduction of a product? This is what the research in IDEAL project Design for Producibility activity tried to answer the question of how to support production engineers to identify, define, structure, share and reuse their requirements to create a common understanding between the design and production domains.

What do the practitioners say is needed to achieve this collaboration and common understanding?

Data analysis from partner companies highlighted that there was a lack of support for production engineers to present their requirements to the design engineers. Support was needed to guide the production engineers to identify and define the requirements, and structure and share them with concerned stakeholders. For the design engineers, the innovation needed not to be constrained in the initial phases. This meant that a method to work with production requirements should consider product and production maturities while providing opportunities for collaborative decision-making for requirement analysis, prioritisation, and knowledge sharing. It is also vital to support the reuse of these requirements as the process is time intensive and time is money.

How can this collaborative decision-making between design and production engineers for production requirements specification be achieved?

A method to work with production requirements was developed along with close collaboration with the partner companies, based on a semi-automated assembly line. It is not enough just to capture the requirements, but also to share and collaborate. For this, the dynamic nature of the maturity product and production system needs to be considered and opportunities for cross-functional requirement analysis should be provided in the method. This is accommodated in the method using Technology Readiness Levels and Lean Production Preparation Process. The method for working with production requirements thus supported the production engineers to identify, define and structure their requirements, share them with design engineers and collaborate for requirement prioritization. The method was demonstrated using commonly used tools such as MS Excel and

Power BI and received positive reviews from the industry.

“The method is an easy way to standardize communication between R&D and manufacturing across different projects while reusing requirements” and “creates structured dialogues between stakeholders”- feedback from practitioners.

Complexities in product development are related to uncertainties such as a different lifecycle for product and production systems, and lack of clarity of maturities. The method presented as a part of this research aims to develop a common understanding and minimize ambiguities. More can be read at the link.

Author

- Doktorand maskinkonstruktion

- Tekniska Högskolan

- rohith.arethkoroth@ju.se

- +46 36-550 2439

Detta är en bloggtext. Det är skribenten som står för åsikterna som förs fram i texten, inte Jönköping University.